Everything You Need to Know About CAD to Point Cloud Conversion

Businesses / Posted 4 months ago by CAD Drafting / 143 views

Computer-Aided Design (CAD) has been the backbone of engineering and manufacturing for decades. But as industries push toward greater precision and real-world integration, professionals are increasingly turning to point cloud technology. Converting CAD models to point clouds opens up new possibilities for quality control, reverse engineering, and Building Information Modeling (BIM) applications.

This comprehensive guide explores the CAD to point cloud conversion process, its applications, and the tools you need to get started. Whether you’re an engineer looking to improve quality control or a designer seeking better visualization capabilities, understanding this conversion process can transform how you approach your projects.

Understanding CAD: The Foundation of Digital Design

Computer-Aided Design (CAD) represents objects through mathematical models, creating precise geometric representations using vectors, curves, and surfaces. CAD software like AutoCAD, SolidWorks, and Fusion 360 allows designers and engineers to create detailed 2D drawings and 3D models with exact measurements.

CAD models excel at representing perfect geometric shapes and theoretical designs. They’re parametric, meaning you can modify dimensions and features while maintaining design relationships. This makes CAD ideal for initial design work, manufacturing specifications, and documentation.

However, CAD models represent idealized versions of objects. They don’t capture the imperfections, wear patterns, or real-world variations that exist in physical objects. This is where point clouds become valuable.

Understanding Point Clouds: Capturing Reality

Point clouds are collections of data points in 3D space that represent the external surface of objects or environments. Each point contains X, Y, and Z coordinates, and often includes additional information like color or intensity values.

Point clouds are created through various scanning technologies:

LiDAR (Light Detection and Ranging) uses laser pulses to measure distances, creating highly accurate point clouds with millions of data points. This technology is commonly used in surveying, autonomous vehicles, and large-scale mapping projects.

Photogrammetry processes multiple overlapping photographs to reconstruct 3D geometry. While less precise than LiDAR, photogrammetry offers a cost-effective solution for many applications and can capture color information naturally.

Structured Light Scanning projects patterns onto objects and analyzes the deformation to calculate depth information. This method works well for smaller objects and provides good detail resolution.

Point clouds excel at representing real-world conditions, surface textures, and complex geometries that would be difficult to model in CAD. They’re particularly valuable for as-built documentation, quality inspection, and reverse engineering applications.

The CAD to Point Cloud Conversion Process

Converting CAD models to point clouds involves several key steps that transform mathematical representations into discrete data points.

Step 1: Model Preparation

Start by ensuring your CAD model is clean and properly scaled. Remove any unnecessary components and verify that all surfaces are properly defined. Complex assemblies may need to be simplified or converted to mesh formats first.

Step 2: Mesh Generation

Most conversion processes require converting CAD surfaces to triangular meshes. This step discretizes the smooth mathematical surfaces into a network of triangular faces that can be more easily processed.

Step 3: Point Sampling

The software samples points from the mesh surfaces using various algorithms. You can control point density, sampling patterns, and coverage areas. Higher density creates more accurate representations but results in larger file sizes.

Step 4: Point Cloud Generation

The sampled points are compiled into a point cloud format, typically with coordinates and normal vectors. Some software can add color information or other attributes based on material properties or surface characteristics.

Step 5: Quality Verification

Review the generated point cloud for completeness and accuracy. Check for gaps, ensure proper density distribution, and verify that critical features are adequately represented.

Key Use Cases for CAD to Point Cloud Conversion

Reverse Engineering

Converting existing CAD models to point clouds creates reference datasets for reverse engineering projects. Engineers can compare scanned parts against original designs to understand wear patterns, manufacturing variations, or design modifications.

Quality Control and Inspection

Point clouds from CAD models serve as reference standards for dimensional inspection. Manufacturers can compare actual scanned parts against the CAD-generated point cloud to identify deviations, measure tolerances, and ensure quality standards.

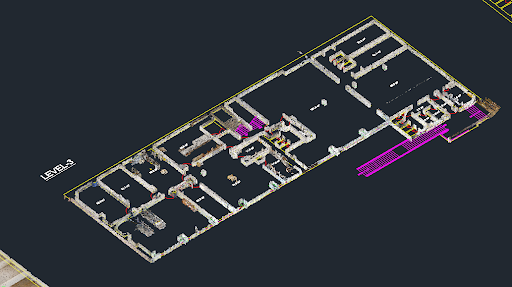

Building Information Modeling (BIM)

Converting architectural CAD drawings to point clouds helps create more realistic building representations. This process supports clash detection, space analysis, and visualization for construction projects.

Virtual Reality and Visualization

Point clouds from CAD models can be integrated into VR environments or visualization platforms that don’t natively support CAD formats. This enables immersive design reviews and stakeholder presentations.

Data Integration

Some analysis software works better with point cloud data than CAD models. Converting CAD to point clouds enables integration with specialized analysis tools, simulation software, or machine learning algorithms.

Software and Tools for Conversion

Several software solutions offer CAD to point cloud conversion capabilities:

CloudCompare provides open-source point cloud processing with CAD import capabilities. It offers flexible sampling options and extensive point cloud manipulation tools.

MeshLab excels at mesh processing and can convert CAD models to point clouds through mesh intermediates. It’s free and offers advanced sampling algorithms.

Geomagic Wrap offers professional-grade conversion tools with advanced sampling controls and quality optimization features. It’s designed for industrial applications requiring high accuracy.

MATLAB provides point cloud processing toolboxes that can convert CAD models programmatically. This is ideal for automated workflows or custom processing requirements.

Specialized CAD Software like SolidWorks, Inventor, and Rhino often include point cloud export capabilities, allowing direct conversion from native CAD formats.

When selecting software, consider factors like supported file formats, point density controls, automation capabilities, and integration with your existing workflow.

Challenges and Considerations

Accuracy Requirements

Point cloud density directly affects accuracy and file size. Higher density provides better surface representation but creates larger files that are harder to process. Balance accuracy needs with practical file size limitations.

Surface Complexity

Complex surfaces with fine details may require higher point densities to maintain accuracy. Curved surfaces, thin features, and intricate geometries need careful consideration during the conversion process.

Data Alignment

Ensuring proper coordinate system alignment is crucial when combining converted point clouds with scanned data. Misalignment can lead to incorrect analysis results and measurement errors.

File Size Management

Point clouds can become extremely large, especially for complex models or high-density conversions. Consider data compression, level-of-detail strategies, and storage requirements early in the process.

Processing Time

Converting large or complex CAD models can be time-intensive. Plan for adequate processing time and consider batch processing for multiple models.

Software Limitations

Not all CAD features translate well to point clouds. Parametric relationships, assembly constraints, and material properties are typically lost during conversion.

Maximizing the Value of CAD to Point Cloud Conversion

CAD to point cloud conversion bridges the gap between idealized design models and real-world data capture technologies. This process enables new workflows in quality control, reverse engineering, and data integration while supporting emerging technologies like digital twins and Industry 4.0 applications.

Success with CAD to point cloud conversion requires careful consideration of accuracy requirements, appropriate tool selection, and understanding of the inherent limitations. Start with simple models to understand the process, then gradually tackle more complex conversions as you build expertise.

As scanning technologies continue to advance and point cloud processing becomes more sophisticated, the ability to seamlessly convert between CAD models and point clouds will become increasingly valuable across industries ranging from manufacturing and construction to archaeology and entertainment.

- Listing ID: 57657

- Country: USA

- City: New York